Why Conveyer Belt Cleaners are Essential for Productivity in the Mining Industry?

- Saptak Biswas

- Aug 27, 2022

- 3 min read

Updated: Sep 19, 2022

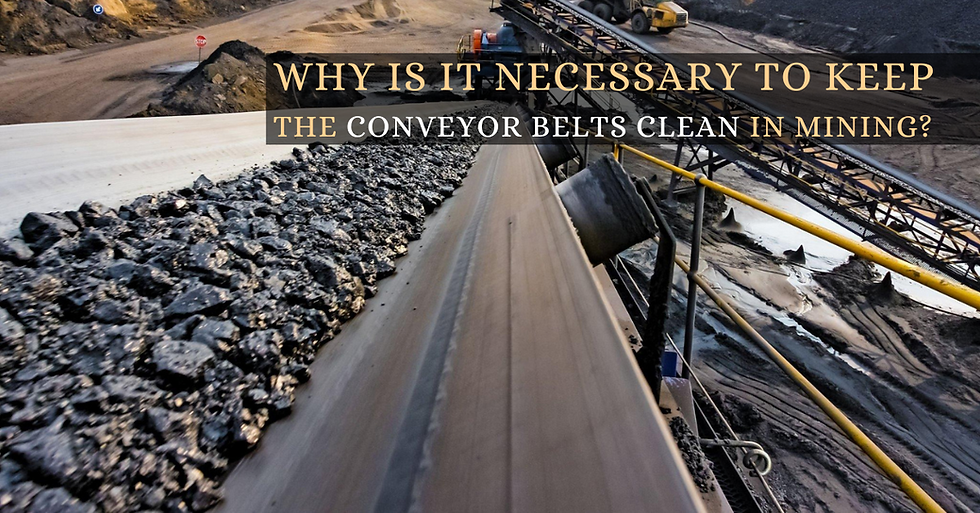

Most conveyor installations now require effective belt cleaning devices. Maintaining a clean belt is one of the most essential components of a conveyor system’s overall efficiency, profitability, and safety. There are primary and secondary belt scraper & cleaner which must be used properly to keep the process safe. So there is a need for conveyor belt cleaners in the mining industry because supplying and carrying heavy loads can lead to various challenges that might affect the operations’ smooth movement.

Conveyor belt cleaners and solutions are used to ensure that there is no or less spillage and carrybacks. A primary cleaner is designed to remove the majority of the carryback from the belt as it passes over the head pulley. Secondary cleaners are installed for more effective cleaning after the primary cleaning is completed.

Brief Introduction of a Conveyor Belt

A conveyor belt is a material handling system that is used in the mining industry to move heavy loads and materials from one point to another point. The belt is one of the most essential parts of the conveyor system. Conveyor Belt is used for handling bulk materials and it has several useful properties which are helpful in transporting heavy materials.

The structure of a conveyor belt has two functional pulleys with a conveyor material over it which helps in carrying bulk materials effortlessly. The conveyor belt system generally depends on other components for its smooth running such as the idlers, rollers, and bearings which help the conveyor system to operate in different temperatures.

Types of Conveyor Cleaners

The operations done by the conveyor belts in the mining industry need proper maintenance which is possible by using cleaning solutions. The cleaning must be very effective as it is responsible for moving bulk materials and the cleaners have to be long-lasting to provide safety.

There are different types of secondary belt scrapers & cleaners:

Primary Cleaners

The primary scrapers and cleaners should be made of urethane. It will function similarly to a metal blade-type scraper but without the risk of metal damage. The belt cleaner should be designed to be compact and modular for mounting.

Secondary Belt Scrapers

It is made of tungsten carbide which is long-lasting and durable. The flaps will ensure that the carrybacks don’t get stored during the conveying of bulk materials. The secondary cleaner can work independently if the materials are dry in nature.

Benefits of a Conveyor Belt Cleaner in a Mining Industry

Removes spillage and carryback - The conveyor belt scraper and cleaner help the materials spill on the machine during its movement from one place to another. The dirt is removed by a proper cleaner. It removes the carryback at the head pulley and ensures the smooth running of the machine.

Providing Profitability and Production - The proper running of the conveyor machine will ensure useful outputs by minimizing debris and unwanted materials. The cleaner will avoid loss in time and have a greater impact on the process.

High Conveyor Belt life - Rollers and idlers are frequently damaged by unrestrained carryback. It also causes drifting, fraying, and mistracking of the belt. The scrapers will save the conveyor belt from much harm and help them serve longer.

Final Words

The need for primary and secondary belt scraper & cleaner is widely essential for the smooth transport of items to the right place in a shorter time. Therefore before using the conveyor system, a proper check of the belts should be done and the cleaners should be checked whether it is properly installed and in running condition.

.jpg)

Comments