Why is it Necessary to Keep the Conveyor Belts Clean in Mining?

- Saptak Biswas

- Sep 19, 2022

- 2 min read

Updated: Dec 5, 2022

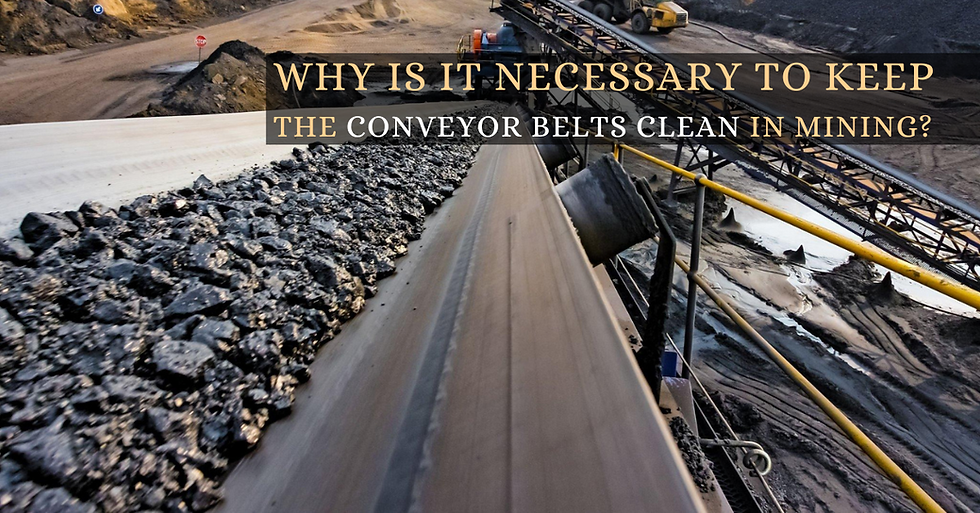

In the mining industry, heavy loads and structures are used in many applications which require easy transportation of the loads from one point to the other. The maintenance of the conveyor belts becomes necessary, failing which might cause a huge loss or can create chaos. For a high-performance conveyor belt to run smoothly, the addition of a primary and Secondary Belt Scraper & cleaner is useful. There are several industrial companies which provide some of the best conveyor belt cleaners that are versatile and cost-effective.

Benefits of Belt Cleaners

Some materials, particularly wet or sticky ones, have a tendency to attach to the belt surface, creating carryback, build-up, and eventually prohibiting the conveyor from running properly. They can damage the wear and mechanical parts which require high maintenance costs.

Several Benefits of using a Belt Cleaner are:

Increases Profitability

When heavy loads are put up on the conveyor belt, it requires proper functioning of the conveyor for smooth and safer transportation. Belt cleaners are installed in the belts to remove the fugitive materials that get stuck and hence increasing the profitability of the work. Proper cleaning of the belts increases the efficiency of the belts which reduces the higher maintenance cost.

Provides Longevity to the Conveyor

The proper installation of the primary and secondary belt scrapers reduces the chance of conveyor equipment damage. Using higher efficiency products for cleaning the unwanted materials that are carried back in the conveyor system, helps in offering a long life to the conveyor.

Reduces Energy Consumption

When the carrybacks are cleaned by the cleaners during the conveying process, the conveyor works smoothly reducing the energy consumption of the machine. The belt cleaners don’t allow the carrybacks to remain at the conveyor belt reducing the work rate and providing efficient running of the component.

Safety for the Worker

The use of belt cleaners reduces the risk of the workers getting harmed or meeting any unwanted accidents. The materials that are scraped might be slippery which might increase the risk of workers falling into the mess. Secondary Belt Scraper & cleaner lowers the risk of the worker's health.

Types of Belt Cleaners

Primary Belt Cleaners

The primary belt cleaner is used to clean any unwanted material stuck at the belt while conveying materials by using the spring-loaded blade or plate attached to the conveyor belt. The primary scraper is the first scraper in the system and is usually in charge of the majority of the cleaning.

Secondary Belt Cleaners

Sometimes when heavy loads are conveyed continuously, the conveyor belt requires more than one cleaning solution that can assure proper cleaning of the belt. It is an additional cleaner that helps the primary scraper in cleaning the belt prominently. This scraper provides an additional level of cleaning and is especially useful when debris continually adheres to the belt.

Conclusion

Therefore in the mining industry, there are various setbacks that can cause heavy accidents or damage to machines that can increase the cost of maintenance. Therefore install the best quality Secondary Belt Scraper & cleaner for smooth movement of the conveyor.

.jpg)

Comments