What Makes Tega Conveying Solutions Unique?

- Saptak Biswas

- Feb 22, 2022

- 2 min read

Updated: Aug 27, 2022

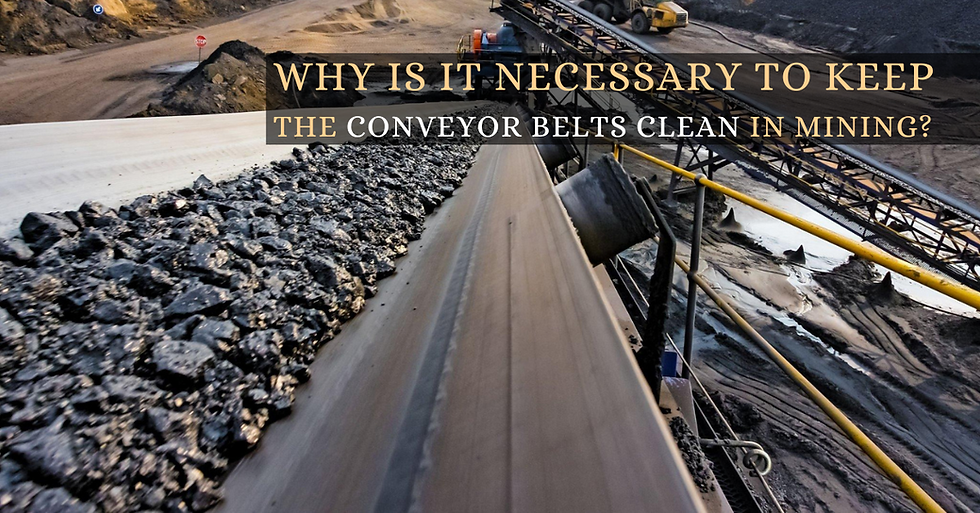

While transporting material from one end to another, there is a high risk of spillage. This is due to the improper size or wear and tear of the conveyer belt.

The main role of the conveyer belt is to meet challenges like:

Material spillage

Belt spillage

Flow-restriction

Carry-back

The parameter of a good conveyer belt changes dynamically, and this happens due to a change in material transportation or the mission of the conveyer. This is why it is important to own a conveyer belt that can withstand the harsh environment of a factory and is flexible enough to grow and expand with the business.

Why You Must Consider Tega Conveyer Belt

Place Utility

Tega believes in providing a solution that fits your industry. Every conveyor belt is not the same, this is why Tega helps in manufacturing customized conveying solutions that fit perfectly with the industry's manufacturing unit. They provide doorstep delivery to the factory.

Time Utility

Tega makes sure there is no spillage. For this, they help in the installation of the conveying solution, like a conveyer belt, primary belt scraper, secondary belt scraper, and cleaner.

With a complete conveying solution, it makes sure there is less shutdown and breakdown, ensuring your industry does not fall short in productivity due to spillage. This helps in better material handling while transporting minerals and ores from one point to another in the mining beneficiary industry.

You May Like: Overview of Grinding Mill Liner

Possession Utility

Tega provides a complete conveying solution. Tega provides you with possession utility, which means you can ask for complete installation and servicing for any bulk material handling problems.

Subsequent Cost

Tega reduces the cost of material handling, as the products do not wear or tear easily. These products are a better asset to any industry compared to other accessories. They also provide installation support, after-sales support, and training to staff for better material handling. This helps in reducing the maintenance and subsequent cost.

Moreover, a good conveying solution ensures there is no wastage of ore during transportation. It requires less manpower and ensures the production does not stop midway.

Tega Provides a Diagnosis and Solution-Based Approach

The study of process and operational parameters helps in better designing the conveyor equipment. Be it Primary Belt Scraper & cleaner, they have a better understanding of the challenges associated with bulk material handling in the mining industry. Tega studies the existing equipment design and brings a new modern approach to Conveyer accessories technology in the industrial workplace.

Expertise and Experience

One of the crucial parts of conveying solution is, the material, design, and transporting of bulk varies from one industry to another. This is where Tega has a crucial role, with over 35 years of experience, Tega's conveying solution is focussed on Audits, Research, development, and value-added oriented consumer interaction.

Conclusion

Conveyer belt, primary scrapper, secondary scrapper, cleaner are part of conveying solution. Each has a crucial role in material transportation in the mineral industry. Tega's product ensures there are little to no shutdowns due to the failure of equipment.

.jpg)

Comments